What is the Difference Between Cross-Docking and Transloading?

08/21/2023 — PartnerShip

It's common in logistics and warehousing to be asked: What is cross-docking? What is transloading? What is the difference between cross-docking and transloading?

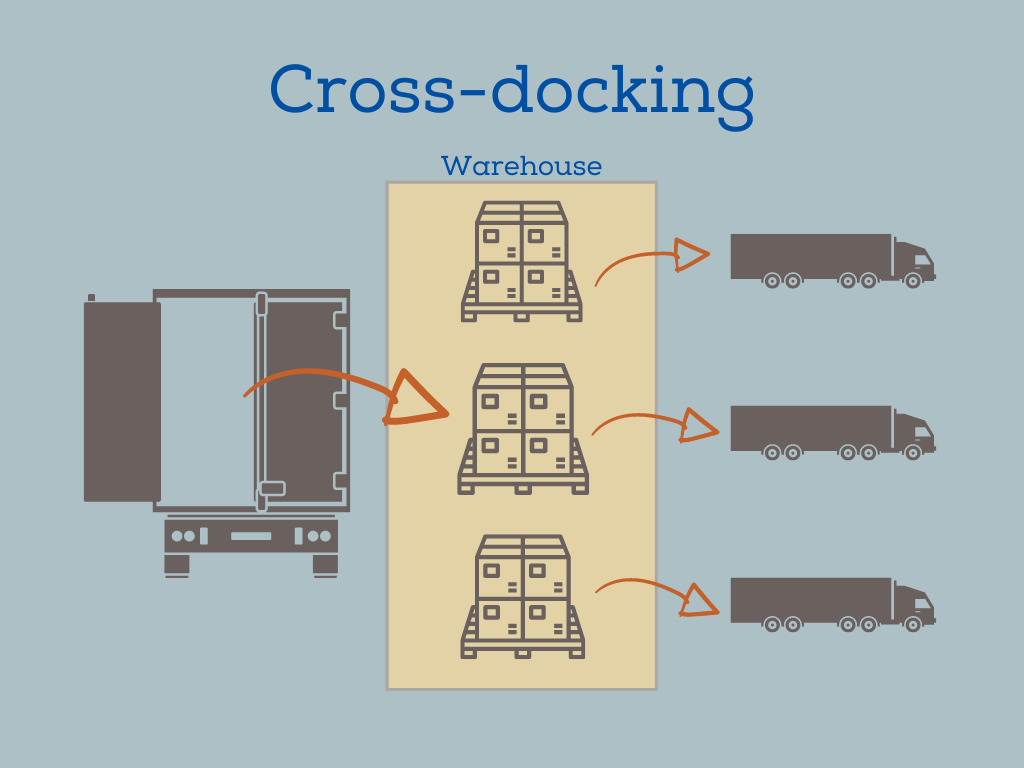

Cross-docking is unloading inbound freight from one truck, holding it in a warehouse or terminal for a very short period of time, and loading it onto another truck for outbound shipping.

Let's look at an example of cross-docking: A manufacturer needs to ship 20 pallets of products from the east coast to destinations in Texas, Florida and California. The 20 pallets are first shipped to a third-party warehouse in Cleveland, Ohio. A day later, 5 pallets are sent to Florida, 10 to Texas, and 5 to California on trucks bound for those destinations. Since the pallets were never unpacked and were only in the warehouse long enough to move them from one truck to another truck (and from one dock to another dock), they have been cross-docked.

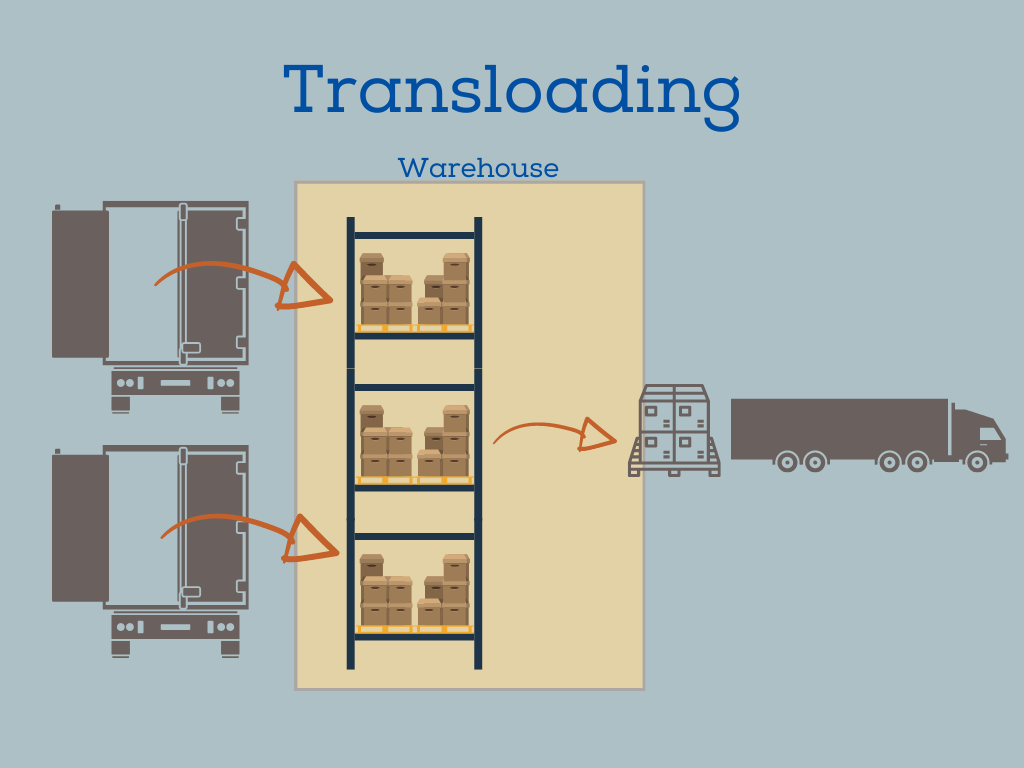

Transloading is when inbound freight is unloaded, the pallets are broken down, and their contents sorted and re-palletized for outbound shipping.

Using the same Cleveland, Ohio third-party warehouse, here is an example of transloading: 5 suppliers of a manufacturer ship a year’s supply of components to the warehouse. The components are stored until they are needed, at which time the warehouse picks them, assembles them into a single shipment, and ships it to the manufacturing facility.

To recap, cross-docking is the movement of an intact pallet (or pallets) from one truck to another, and transloading is the sorting and re-palletizing of items.

Both cross-docking and transloading services are specific logistics activities that can create benefits for businesses; especially ones that utilize a third-party warehouse.

Benefits of cross-docking

- Transportation costs can be reduced by consolidating multiple, smaller LTL shipments into larger, full truckload shipments.

- Inventory management is simplified because cross-docking decreases the need to keep large amounts of goods in stock.

- Damage and theft risks are reduced with lower inventory levels.

- With a decreased need for storage and handling of goods, businesses can focus their resources on what they do best instead of tying them up in building and maintaining a warehouse.

- Businesses can store goods and products near customers or production facilities and have them shipped out with other goods and products, decreasing shipping costs.

- Businesses can ship full truckloads to a third-party warehouse instead of many smaller LTL shipments.

- With storage and logistics managed by others, the need for building and maintaining a warehouse is eliminated.