the PartnerShip Connection blog

the PartnerShip Connection blog

the PartnerShip Connection blog

the PartnerShip Connection blog

the PartnerShip Connection blog

-

Your Guide to the 2019 FedEx and UPS Rate Increases

12/17/2018 — Leah Palnik

FedEx and UPS rates will be going up in 2019, and it’s more important than ever that shippers know how to mitigate the impact to their business. In November, FedEx announced that its small package rates will increase an average of 4.9% as of January 7, 2019. In December, only a few weeks before the change is set to take place on the 26th, UPS announced the same average increase.

If you’re thinking that means you can budget your costs to go up by 4.9%, you are sorely mistaken. There is a lot to unpack with these rate increases. For starters, some services are increasing at a higher rate than others – meaning that depending on the services you commonly use, your costs could go up significantly more than the announced average.

Other factors determine how much more you will pay for your FedEx and UPS shipments in 2019. You will need to look at the new rates based on your package characteristics, as well as how far your shipments are being sent. Here are the released rates for 2019:

FedEx and UPS surcharges

The announced average increase only covers the base rates. You’ll also need to consider what fees and surcharges apply to your shipments. Many of these surcharges are increasing quite a bit. Here are the announced changes:One surcharge to take note of is the Third-Party Billing fee. A couple years ago, UPS introduced this in response to the growing popularity of drop shipping. Right now if you use third-party billing, you will incur a charge of 2.5% of total cost. Beginning December 26, UPS will be increasing that charge to 4.5%. FedEx is leaving its Third-Party Billing charge unchanged at 2.5% for 2019. This is just one example of why it’s important to evaluate the changes that come out each year from UPS and FedEx. One small difference can have a huge impact on your costs.

The most costly surcharges continue to be those that apply to shipments that qualify as “Unauthorized” or “Over Maximum Limits.” If you send a package with UPS that weighs more than 150 lbs., exceeds 108 inches in length, or exceeds a total of 165 inches in length and girth combined, you’ll be looking at a $850 charge on top of your base rate. That same package will incur a $675 charge if you ship it with FedEx. Either way, you’ll be paying a huge premium to ship larger, bulkier packages.

Peak season strategies

It’s also important to note that ahead of the 2019 general rate increase (GRI), FedEx and UPS both announced peak season surcharges. For those larger packages, the carriers applied additional surcharges during the busiest time of year. A huge difference between the two, however, was an additional charge on residential shipments. UPS applied a $0.28 peak surcharge on residential ground shipments, while FedEx decided that for the second year in a row, it wouldn’t follow suit. If you’re a retailer that delivers a large amount of customer orders over the holidays, that charge can add up fast.Trends in the small package industry

If you zoom out on all of these changes from FedEx and UPS, there are a few insights to glean.- FedEx and UPS tend to institute similar pricing strategies. The carriers have a habit of matching each other when announcing average increases, and when one introduces a new charge or a different way to account for something, the other tends to do the same down the road. That doesn’t mean that it doesn’t matter which carrier you use. Instead, it’s important to stay on top of the changes and evaluate your options on a regular basis so you’re always using the service that works best for your budget.

- Many of the changes over the years have been put in place as a result of the ecommerce boom. With more shipments coming from online orders, comes more trends that strain the carriers’ networks. For example, ecommerce has led to more residential deliveries and more deliveries of oversized packages. That’s why you’ll see the carriers making changes that help them to recoup some of the costs associated with these trends.

- Both carriers have been making changes throughout the year, instead of just during the GRI. For example, FedEx and UPS both increased their Additional Handling surcharges ahead of the new year – in September and July respectively. When UPS first introduced peak surcharges for residential ground shipments, that was also done outside of the annual announcement. This just highlights how important it is for shippers to stay aware throughout the year.

We know you don’t want to comb through every tedious page of the 2019 FedEx and UPS service guides and compare them to your current rates. That’s why we did the leg work for you. In our free white paper, we break down where you’ll find the highest increases and explain some of the complicated changes you need to be aware of. If you’re looking for ways to offset the rate increases, we can also help with that. If you’re a member of one of the many associations we work with, you can get access to exclusive discounts. Contact us and we’ll find a way to help you save.

Click to read more... -

It's a Throwback PartnerShip Holiday!

12/17/2018 — Jen Deming

It's the time of year for good cheer, gift giving, and family get-togethers. One of the best parts about bringing everyone together for the holidays is flipping through old albums and boxes of family photos to relive memories from holidays gone by. We wanted to share some of our team's favorite throwback holiday photos with you, and wish everyone the happiest of holidays from our family to yours!

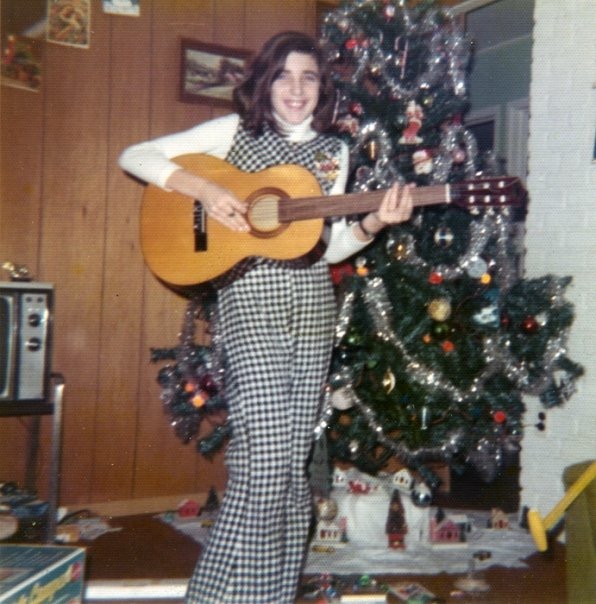

Barbara Teleha, Graphic DesignerBefore flexing her creative muscle as the PartnerShip resident designer, Barbara was striking chords in checkered onesies and turtlenecks

Barbara Teleha, Graphic DesignerBefore flexing her creative muscle as the PartnerShip resident designer, Barbara was striking chords in checkered onesies and turtlenecks

Jennifer Hammersmith, Customer Service Manager'Tis the season to be "married" and bright for Jennifer and her husband, Dave!

Jennifer Hammersmith, Customer Service Manager'Tis the season to be "married" and bright for Jennifer and her husband, Dave!

Jerry Spelic, Marketing DirectorJerry celebrates with a themed tree every year: Meet Spencer Tree-cyChristine Manda, Freight Brokerage Sales Manager

Jerry Spelic, Marketing DirectorJerry celebrates with a themed tree every year: Meet Spencer Tree-cyChristine Manda, Freight Brokerage Sales Manager

Christine and sister get festive while rocking around the Christmas TreeBrian Hardman, Senior Account Representative and Nicole Hardman, Senior Carrier Procurement Representative

Christine and sister get festive while rocking around the Christmas TreeBrian Hardman, Senior Account Representative and Nicole Hardman, Senior Carrier Procurement Representative

The Hardman husband/wife team toast their first Christmas togetherLeah Palnik, Marketing Manager

The Hardman husband/wife team toast their first Christmas togetherLeah Palnik, Marketing Manager

Leah celebrates the holidays with her childhood furry friend, FiggieShaunta Dennis, Customer Service Representative

Leah celebrates the holidays with her childhood furry friend, FiggieShaunta Dennis, Customer Service Representative

Shaunta patiently awaits the arrival of her gifts - as an adult she makes sure PartnerShip customers get their packages on timeKeith Korhely, Senior Program Manager

Shaunta patiently awaits the arrival of her gifts - as an adult she makes sure PartnerShip customers get their packages on timeKeith Korhely, Senior Program Manager

Keith's buddy Gigi thinks she's all the gift that anyone needsJosh Arnold, Programmer Analyst

Keith's buddy Gigi thinks she's all the gift that anyone needsJosh Arnold, Programmer Analyst

Josh offers an interesting take on Santa Claus at a past PartnerShip Christmas partyBill Parhamovich, Account Representative

Josh offers an interesting take on Santa Claus at a past PartnerShip Christmas partyBill Parhamovich, Account Representative

Bill recites his Christmas list to Santa, it may or may not include a Red Ryder BB GunJen Deming, Marketing Associate

Bill recites his Christmas list to Santa, it may or may not include a Red Ryder BB GunJen Deming, Marketing Associate

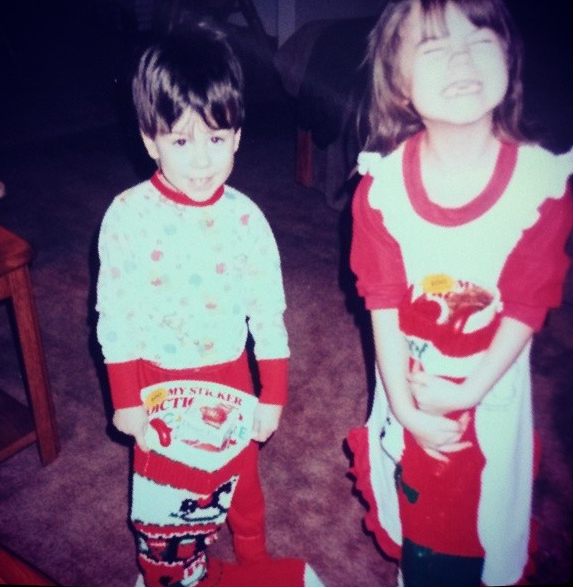

Jen and brother Matt decide all they want for Christmas is EVERYTHING

Jen and brother Matt decide all they want for Christmas is EVERYTHINGMaking merry memories is one of our favorite parts of the holiday season, and we look forward to what this year will bring! Happy Holidays from our family to yours!

Click to read more... -

6 Surprising Advantages of Rail Transport Over Road Transport

12/13/2018 — Leah Palnik

Road transport is a very popular mode for freight, but for certain loads, the advantages of railways are too great to ignore. If your shipment is moving over 1,000 miles and isn’t time sensitive, rail transport can be a very efficient solution for your supply chain.

Here are some advantages of rail transport over road transport to consider:

- Rail transport can be cost effective. Shippers who convert long-haul freight from road to rail, can save 10-40%. Rail has lower fuel costs compared to road transport, especially when shipping a high volume of freight. Rail also has less costs associated with drivers and typically has better costs for drop trailer programs.

- Shipping via train is more environmentally friendly. Trains burn less fuel per ton mile than trucks. According to the Association of American Railroads (AAR), freight railroads can move one ton of freight an average of 479 miles on a single gallon of fuel. On top of that, using rail transport over road transport can lower greenhouse gas emissions by 75%.

- Trains are capable of hauling large loads. Trains can handle high volumes of freight. In fact, one double-stacked train can hold approximately the same amount as 280 trucks. This can be very beneficial for shippers with large loads.

- Railways are reliable. Railways have standardized transit schedules and don’t share their tracks with the public like trucks do with the road. For that reason, trains aren’t hindered by traffic and weather the same way trucks are.

- Rail freight can be efficient. For many types of loads, the average transit time is comparable to that of road transport. While rail shouldn’t be used for time-sensitive shipments, it can provide very similar transit times for longer hauls.

- Rail options provide you with access to capacity. OTR capacity is tight. The driver shortage, HOS restrictions, and current market demand can make it hard for shippers to find a truck when they need it without paying an arm and a leg. Since rail transport can be more efficient and doesn’t have the same kind of limitations, this is a great way for shippers to find capacity.

Rail as part of an intermodal strategy

Using rail transport as part of an intermodal strategy can have significant benefits. Intermodal is the use of two or more modes for transporting freight. When combining road and rail, trains are used for the long-haul portion of the shipment. Trucks are used to bring freight from the origin to the terminal and then from the terminal to the destination, which is referred to as drayage. Commodities that are typically moved via intermodal rail include electronics, clothes, machinery, plastics, and lumber.Limitations of rail

While rail transport can be a great solution for many shippers, it isn’t for every load. There are some limitations to consider. First, the shipper and the consignee should be no more than 100-200 miles from a major metro area that has a terminal. Also, there aren’t guaranteed transit times, so it’s not recommended for time-sensitive loads.You also want to make sure that you aren’t trying to ship prohibited or restricted articles. Prohibited articles include commodities that are dangerous or could damage equipment, like carbon black, raw animal hides, and used auto parts that leak. Restricted commodities require permission ahead of time and may be constrained to certain lanes or subject to different pricing.

In addition, it’s incredibly important that you are using the proper block and brace techniques. Intermodal containers experience a great deal of movement during transit that could cause damages. If you haven’t blocked and braced your freight by rail standards you run the risk of a denied claim.

Is rail transport right for your freight?

If you think intermodal transportation may be a good fit for your freight, the team at PartnerShip is ready to help. We'll find the solution that best fit your needs, so you can ship smarter. Contact us today to find out what your options are and see how much you could save.

Click to read more... -

6 Sneaky (But Avoidable) Tradeshow Logistics Costs

12/04/2018 — Jen Deming

Anyone who has ever shipped to an event is probably familiar with the special level of stress and frustration involved in coordinating show shipments. Tradeshow logistics is tricky business - not only are you juggling crunched timelines leading up to the show, but shippers also have to be aware of the many potential hidden costs involved throughout the process. Any misstep can end up costing shippers in surprise freight fees. The good news is that most of these costs are avoidable, as long as you know what to look out for. We've compiled a list of the things you need to keep an eye on to protect your special event freight spend.

- The cost of shipping to advance warehouse vs. show site

You have the choice to ship directly to the tradeshow floor or to an advance warehouse where your show materials are held leading up to the actual show start date. There are advantages and disadvantages to both, and as an informed shipper you need to weigh what makes the most sense for you. Shipping to an advance warehouse will give you more time to be flexible should anything go wrong or be delayed. Though material handling fees may be slightly higher, it doesn't cost more to ship to the advance warehouse. An added benefit is less worry about whether your shipment will arrive on time, and you get a leg up on the shipments arriving to the show site. Your shipment materials will be ready and waiting for you at your booth space when you arrive the day of set-up.

Shipping directly to site can be tempting to avoid these initial material handling costs, but keep in mind that hundreds of other event shipments will be arriving at the same time as yours. If you've never seen a show-site marshaling yard, think of a rush-hour traffic jam during the last weekend of holiday shopping season. It's not pretty, and hold-ups cost lots of money in detention fees. If your shipment arrives late, the team waiting to build your booth will pass on overtime charges. If you're running extra-late, springing for expedited transportation charges will cost you even more. We've said it before, and we'll say it again: plan ahead, and build in extra time. Make your decisions based on what realistically makes the most sense for your business.

- Delivering or picking up your shipment in overtime

The exact time your tradeshow shipment is loaded or unloaded is critical, and meeting your target time will save you significantly. In addition to open dates for both the advance warehouse and show site, there is a window of hours called straight time. These are the hours, and days, your shipment needs to arrive for the show in order not to be hit with overtime fees. This window is usually restricted to typical work hours, 8:00 am to 4:00 pm, for most shows, Monday through Friday. Anything that arrives after those hours, or on the weekends, will be considered overtime and incur extra charges. It is critical to check in your exhibitor packet exactly what hours and dates are safe for your shipment to arrive prior to the show.

You also need to make sure your specific check-in time is noted on the material handling form, especially if your carrier arrives early. Often, a truck will arrive the night before, ahead of schedule. If there's no time noted, the driver may check in and get loaded on overtime, and this will increase your bill significantly. A great best practice to stick to is writing "load only during straight hours" in order to diminish the likelihood it will be loaded outside of that time, as well as act as documentation to help your case should your freight be loaded during overtime and you want to dispute the extra charge.

- The price of damages and how freight insurance can help

Shipment damage or loss can occur at any time. While carriers do everything they can to keep them from happening, it's just an unfortunate part of freight shipping. With your load moving in and out of several different terminals (especially if your freight is traveling a greater distance), your shipment may encounter a renegade forklift or a heavy-handed loader. That's why it is key to package appropriately and securely. Custom crates are a great idea, especially for furniture and other fragile booth materials. Imagine arriving to a show and your seating is damaged and unusable. Sure, you have the option to rent a couch but it's going to cost you thousands for rental in addition to any repairs you will have to spring for to get things in working order for the next show.

Because carrier liability is limited, it's always a good idea to look into additional freight insurance as a secondary option. Tradeshow shipment yards, docks, storage rooms, and show floors are all very congested places. Accidents happen, and should they happen to your show materials, at least you know your freight's full value is covered. Just keep in mind that every third-party insurance provider has different terms, so read carefully and make sure you fully understand the coverage you are getting.

- Using the wrong NMFC and the risk of re-class

Did you know that materials being shipped to events have their very own class code? Don't worry, unless you are shipping to tradeshows regularly, most shippers don't either. Instead of calculating your shipment based on commodity type (furniture, signage, etc), any item either coming to or departing from a tradeshow should be rated Class 125. This can very well mean that the class is different than what you may be using on other shipments, and as a result, the price could be different than what you are used to seeing. It is important to get this quoted correctly, so if you are tempted to use a lower code because it's what you are used to, beware the risk of re-class. You don't want to receive surprise charges/fees when the carrier catches on and your shipment is rated higher than you wanted. The good news is that many booth material items such as chairs or desks tend to ship at a class higher than 125 anyway, so using a preset tradeshow-specific class code may save you.

- Material handling and drayage fees

Material handling and drayage are common fees incurred by event shippers, and often the least anticipated. This type of handling refers specifically to transportation services from your carrier's delivery vehicle, at the dock, to your booth space. These services include unloading at the dock, moving your materials, as well as storing your empty containers for the duration of the show. Once the show is over, gathering the empty containers from storage as well as transferring the freight back to the loading dock will also incur fees. A top recommendation for tradeshow shippers is to crate your loads, rather than sending loose boxes. Some show decorators charge drayage based on how the shipment is packaged. Crating is the least expensive option and also adds protection against damage and loss by keeping your materials together.

Completing a material handling form is crucial to setting up your outbound shipment accurately. Shippers know to have an accurate BOL prepared, but a material handling form is what the decorator looks at. The carrier name for pick-up must be noted, otherwise you will fall victim to "forced freight." This means the shipment will be sent with the decorator's carrier of choice, and that can be pricey. If it's a carrier your 3PL works with (for PartnerShip, UPSFreight or YRC Freight) an LOA can be submitted so you will be billed at your discounted pricing. If not, then you will need to pay the bill direct to the carrier.

The tough part about drayage fees is that these services will be performed by a specific decorator that is under contract with the show. That leaves no room for shippers to negotiate with other options the way you might with transportation to and from the event location. However, there are ways that event shippers can try to keep these costs down as low as possible, particularly regarding packaging. The biggest factors determining drayage fees are weight and piece count. Each piece may be assessed a minimum charge, so make good use of palletizing or crating those loads! They are easier to transport to and from the showroom. Go lightweight for additional savings. Heavy building materials for your booth items will quickly increase your drayage bill, so stick to lighter more transportable building options for your booth tables and seating.

- Shipping there and back for separate shows

It pays to put the time in to accurately plan how much product, booth materials, marketing collateral, giveaways, and anything else you may need. Successful event shippers create a strategy for what needs to be done before, after, and during the show. Check into any information regarding the tradeshow traffic from past years. Talk to the event coordinators and point people to gauge what you think you will need. Anticipate and plan for a little extra, but don't over do it. If you are going to be shipping to another show, look into whether it is more cost efficient to move directly to the next event rather than scheduling a return shipment back home. Very often, the storage fees at the next show location's warehouse may be cheaper than it would be to ship home then ship back out. You will have added peace of mind, again, that your shipment will arrive with enough time before the show so that you can concentrate on and prepare for the next show rather than worrying whether it will arrive on time.

Managing tradeshow logistics can wear on the patience of even the most seasoned of shippers. Meeting deadlines and managing the details can be tough, and it can be tempting to step away and just hope everything goes smoothly. But, it pays to be diligent and well-informed, because that's the best way you can protect your bottom line from hidden tradeshow costs. If you're still feeling a little overwhelmed this tradeshow season, don't worry - the experts at PartnerShip can help. Call 800-599-2902 to speak with a tradeshow shipping specialist, or download our free white paper for more information about tradeshow shipping.

Click to read more... - The cost of shipping to advance warehouse vs. show site